C-pillar repairs go beyond aesthetics in auto body work, being vital for vehicle stability and safety. Specialized shops use advanced techniques and high-quality materials to precisely realign and replace damaged components, ensuring structural integrity while meeting original manufacturing standards. This meticulous process involves thorough inspections, visual examinations, measurements, and testing by trained technicians, with digital documentation enhancing transparency. Prioritizing best practices, including high-quality parts, comprehensive technician training, laser alignment, and CAD software, ensures superior quality and safety in C-pillar repairs, fostering customer satisfaction and meeting industry standards.

In the intricate world of auto body restoration, the C-pillar stands as a structural cornerstone. This article delves into the critical aspects of C-pillar repair and quality control within auto body shops. We explore why this repair is an essential component in auto body work, highlighting its impact on vehicle safety and longevity. By implementing robust quality control measures and adopting advanced techniques, shops can ensure precise repairs, preserving both structural integrity and aesthetic appeal, ultimately satisfying customers seeking top-tier craftsmanship.

- Understanding C-Pillar Repair: The Essential Component in Auto Body Work

- Implementing Effective Quality Control Measures for C-Pillar Repairs

- Best Practices and Advanced Techniques for Ensuring Longevity and Safety

Understanding C-Pillar Repair: The Essential Component in Auto Body Work

In the intricate world of auto body work, the C-pillar stands as a cornerstone, literally and metaphorically. This structural element, often hidden from view, plays a pivotal role in a vehicle’s overall stability and safety. A well-executed C-pillar repair isn’t just about restoring aesthetics; it ensures the vehicle’s structural integrity remains intact after any collision or damage. The process involves meticulous precision to realign and replace damaged components, matching them perfectly with the existing frame for seamless fusion.

Auto body shops that specialize in such repairs combine advanced techniques with a keen eye for detail. Using state-of-the-art equipment and high-quality materials, they navigate the delicate balance between repairing and replacing sections of the C-pillar. The ultimate goal is to deliver a vehicle restoration that meets or exceeds original manufacturing standards, guaranteeing both safety and peace of mind for the driver. This meticulous approach extends beyond mere fender repair; it encompasses the entire vehicle body shop’s commitment to excellence in their craft.

Implementing Effective Quality Control Measures for C-Pillar Repairs

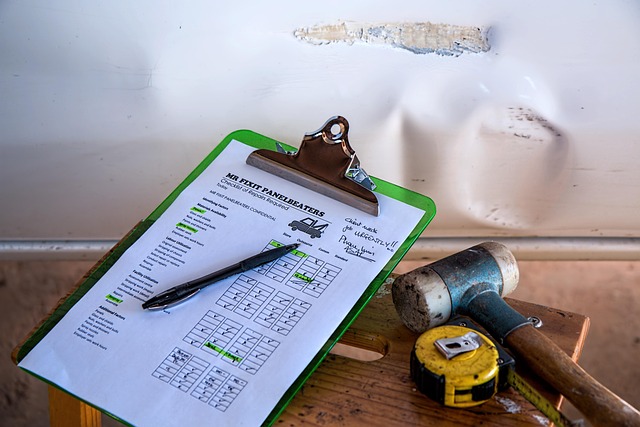

In the realm of auto body shops, ensuring the quality of C-pillar repairs is paramount. Effective quality control measures not only guarantee structural integrity but also contribute to the overall safety and longevity of vehicles. A well-established process includes meticulous inspection, utilizing advanced diagnostic tools to identify any defects or misalignments. This initial step sets the foundation for successful repairs, aligning with industry standards.

Implementing robust quality control involves a multifaceted approach. Trained technicians conduct comprehensive visual examinations, supplemented by precision measurements and testing protocols specific to C-pillar components. Simultaneously, integrating digital documentation ensures clear records of repairs, facilitating future reference and enhancing transparency. Such meticulous practices transform collision repair shops into centers of excellence for vehicle body repair, ensuring cars return to the road safely and reliably.

Best Practices and Advanced Techniques for Ensuring Longevity and Safety

To ensure the longevity and safety of C-pillar repairs in a collision repair shop, adopting best practices and advanced techniques is paramount. Start by utilizing high-quality replacement parts that meet or exceed original equipment manufacturer standards. Proper training for technicians is crucial; they should be adept at identifying damage, disassembling components safely, and accurately measuring and replacing the C-pillar.

Advanced techniques such as laser alignment and computer-aided design (CAD) software enhance precision during repairs. These tools ensure that the C-pillar and surrounding structure are aligned perfectly, maintaining the car’s structural integrity and safety features. Regular quality control checks at every repair stage further mitigate errors, guaranteeing a durable fix that adheres to industry standards, thus enhancing customer satisfaction with top-tier car collision repair services.

C-pillar repair is a critical aspect of auto body work, demanding meticulous attention to detail and adherence to quality control measures. By implementing best practices and advanced techniques, as discussed in this article, auto body shops can ensure the longevity and safety of vehicle structures. Consistent training, precise measurements, and rigorous testing are key to mastering C-pillar repair, ultimately enhancing the overall quality and safety of vehicles serviced in their facilities.